Industrial Internet of Things

IIoT has revolutionized industrial manufacturing by enabling access to greater amounts of data both quickly and more efficiently. A number of innovative companies have started to implement IIoT by leveraging intelligent, connected devices in their factories.

Industrial Internet of Things

The industrial internet of things is an interconnected web of devices that can be monitored from a remote location. Additionally, such devices can monitor and communicate with each other through advanced computer programs and algorithms.

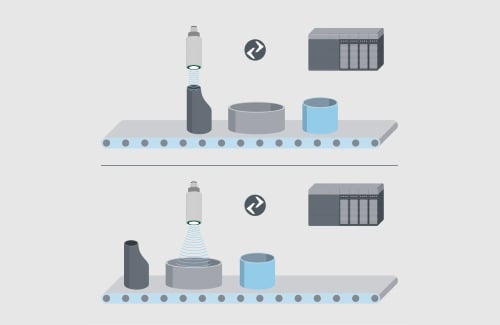

Pepperl+Fuchs Comtrol's IO-Link master gateways provide the most versatile industrial IO-Link master solutions supporting the industry’s leading protocols, including EtherNet/IP, PROFINET IO, and Modbus TCP. The masters come with a full web-based configuration approach with no need for any additional software or a higher-level PLC.

Together with an integrated OPC UA interface, the IO-Link masters are the ideal solution for cloud-based applications—paving the way for future Industry 4.0 scenarios.

Did you know that ...

Benefits

Complete Integration

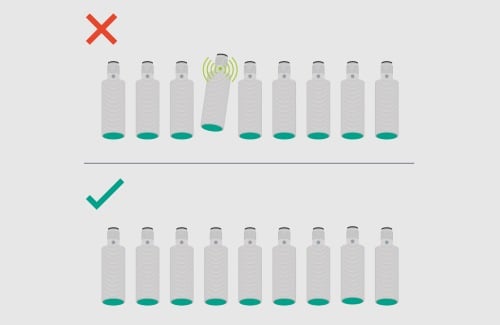

Easy Sensor Replacement

Increased Uptime

Features of IO-Link

Contact Us

What advantages does IIoT offer for my plant? How do I incorporate the technology into my existing communication system? We are happy to answer these and other questions. Just send us a message or arrange a personal consultation with one of our experts.

More Information

More Information

- IO-Link Portfolio Get to know our comprehensive IO-Link portfolio.

- IO-Link North American Competency Center Pepperl+Fuchs Comtrol is North America’s designated IO-Link Competency Center.

- IO-Link 101: Top Ten Benefits Explained Learn about the top ten reasons you should consider switching to IO-Link technology.

- Learn About MultiLink™ MultiLink™ – Simultaneously Provides IO-Link Device Access to Multiple Controllers

- IO-Link Blocks Get to know the new Industrial IO-Link Blocks.